What Is EPE Foam?

EPE Foam is a closed-cell, high-resilience polyethylene material filled with microscopic air bubbles that absorb and disperse impact. Unlike traditional foams like EPS (Expanded Polystyrene), EPE is softer, more flexible, and fully recyclable, making it a sustainable choice for modern protective packaging.

Technical Specifications:

| Property | EPE Foam Performance |

| Density | 18-40 kg/m³ (customizable) |

| Compression Strength | 32-70 kPa |

| Resilience Rate | ≥98% (Returns to original shape even after compression) |

| Water Absorption | <0.1g/cm³ (Waterproof & moisture-resistant) |

| Eco-Friendly | Non-toxic, odorless, and recyclable |

ECOSYSTEM

Key Benefits of EPE Foam Packaging

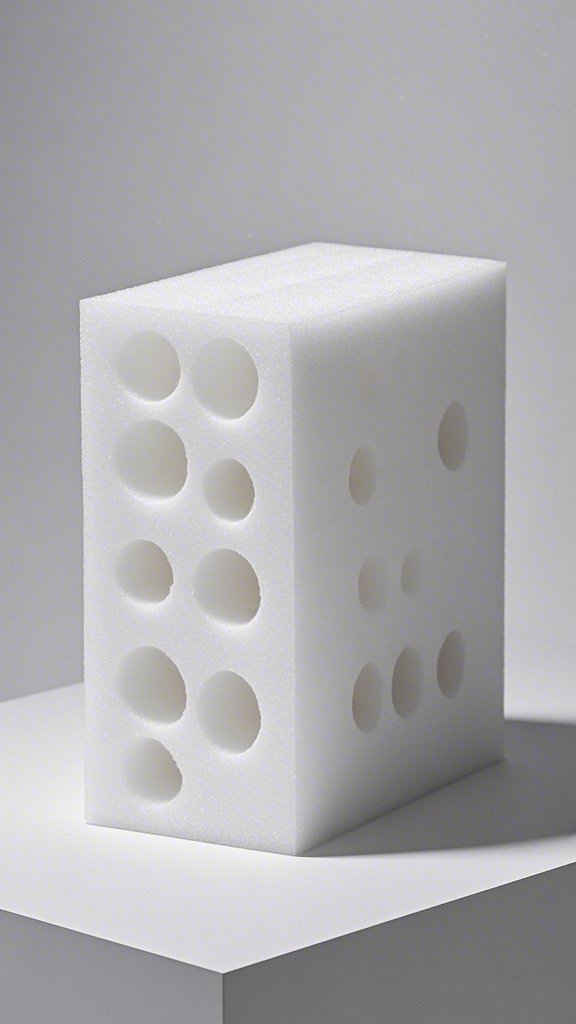

Exceptional Shock Absorption & Impact Resistance

The high-elasticity multi-cell structure absorbs shocks, reducing impact damage by over 30% compared to traditional EPS foam.

Lightweight & Cost-Efficient

15%-30% lighter than traditional foams, cutting down shipping costs.

2-3 times more durable than standard foam, reducing packaging waste.

100% Recyclable & Eco-Friendly

Non-toxic and odorless, suitable for industries moving toward sustainable packaging.

Waterproof, Moisture- & Corrosion-Resistant

Ideal for protecting electronics, precision instruments, and fragile goods.

Resistant to acids, alkalis, and most industrial chemicals.

Highly Customizable for Different Applications

Available in sheets, rolls, tubes, and custom-molded inserts.

Can be enhanced with EVA foam, aluminum foil, anti-static coatings, and more.